PROJECT DESCRIPTION

Delta provided multi-discipline engineering services for the entire complex which included:

- Structural design of deep and shallow foundations

- Mechanical HVAC design

- Plumbing design

- Fire Protection design (excluding QTA facility)

The O’Hare Multi-Modal Facility (previously named Joint Use Rental Car and Public Parking Facility or JUF) is a multi-level, multi-modal parking complex in the north-east quadrant of O’Hare Airport on property that was previously occupied by Public Parking Lot F. The MMF consists of:

- 2,500,000 SF, five-story Consolidated Rental Car Facility (CONRAC)

- 240,000 SF, three-story Quick Turn Around (QTA) rental car maintenance facility

- 7,500 SF, one-story QTA Support Facility

- Airport Transit System (ATS) Station which links travelers to airport terminals

The CONRAC is the hub for travelers coming from, and getting to, the airport terminals. The ground floor contains bus lanes where shuttles will connect the nearby Metra Station to the OMMF. The ground floor hosts the bus and rental car customer lobbies (75,000 SF). Additionally, there are back offices, support services for travelers, and 6,700 total spaces for rental car and public parking.

The connected QTA facility is dedicated to rental car operations. On each of the three floors are four vehicle fueling islands, five carwash bays, and eight maintenance bays. Other spaces include administrative offices, restrooms, and equipment rooms.

The O’Hare ATS people mover system is extended from economy Parking Lot E over Mannheim Rd to the OMMF. There are dedicated entrance and exit roads/ramps to and from the facility.

DELTA-DESIGNED CONRAC FEATURES

- 300,000 SF of hydronic snowmelt and slab heating systems in both OMMF and QTA

- Four VAV air handling units serving the bus lobby, offices, and CSC core lobbies

- Two CAV air handling units serving the CSC lobby

- Water-cooled Chillers (two) and Condensing Boilers (two) serving all air-handling units and terminal units (two of each, located on the fourth floor of the garage)

DELTA-DESIGNED QTA FEATURES

- Island Fueling Stations (12 total, four on each level): with high- and low-level exhaust grills for ventilation, and a central AFFF (foam) system with automatically controlled flow and collection system for discharged foam

- Wash Racks (15 total, five on each level): collects carwash wastewater and completely recycles it after treatment for the initial wash cycle. Harvested rain water treated via reverse osmosis for use in final rinse cycle. Resulting water usage is reduced by 65%.

- Maintenance Bays (24 total, eight on each level): hydraulic lifts, compressed air, lubrication, and oil change systems served by two rooftop makeup air units

- 5,000 MBH Condensing Boilers (eight total): serve the QTA and QTA support buildings’ heating needs and the entire facility slab heating for snowmelt

- One Rooftop VAV unit: serves offices, fuel monitoring, security, and fire marshal command center in the QTA Support Building

- Two Rooftop VAV units: serve the offices, bathroom, and locker rooms on all three levels of the QTA building

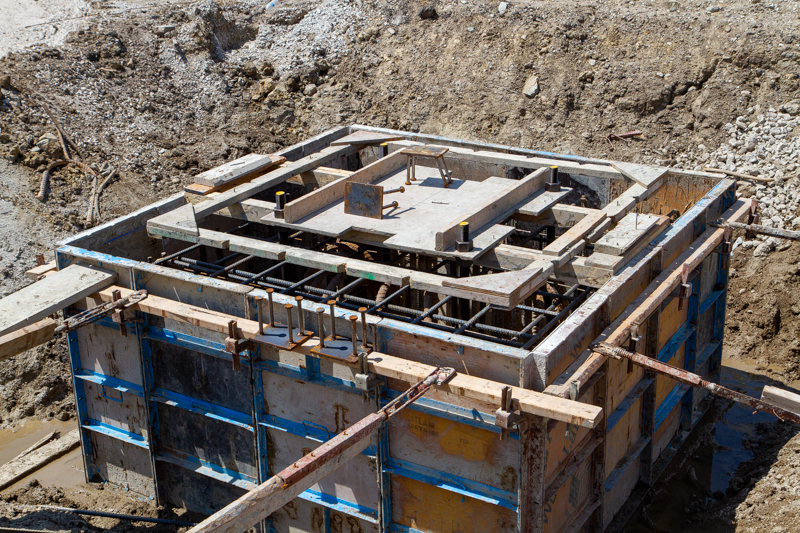

DELTA STRUCTURAL DESIGN

- Deep Foundation Caissons with Caisson Caps (590 total): these rock-bearing caissons vary in diameter from 2’ to 7’ and support the entire pre-cast, pre-stressed concrete superstructure of the CONRAC, QTA, vehicle ramp helices, and architectural elements.

- CONRAC and QTA: 6” concrete slab-on-grade, perimeter grade beams, elevator and escalator pits

- QTA Basement: includes slab-on-grade, walls, roof beam and roof slab design for vehicular loadings

CLIENT

Chicago Department of Aviation

PROJECT LOCATION

O’Hare International Airport

DELTA’S ROLE

Subconsultant

SERVICES PROVIDED

Mechanical Engineering

Plumbing & Fire Protection

Structural Engineering

DESIGN SCHEDULE

01/2012 – 03/2016

CONSTRUCTION SCHEDULE

05/2016- 11/2018

CONSTRUCTION VALUE

$405,000,000

PROJECT SORT LINKS

PROJECT PHOTOS ALBUM #1

Construction progress photos taken in July of 2017. Foundation elements designed by Delta are easily observed prior to erection of the superstructure.

PROJECT PHOTOS ALBUM #2

Punchlist Walkthrough photos for mechanical and plumbing scope at the ‘Quick Turn-Around’ facility. Photos taken in September of 2017.